Introduction: The Rise of Soft Robotics on Water

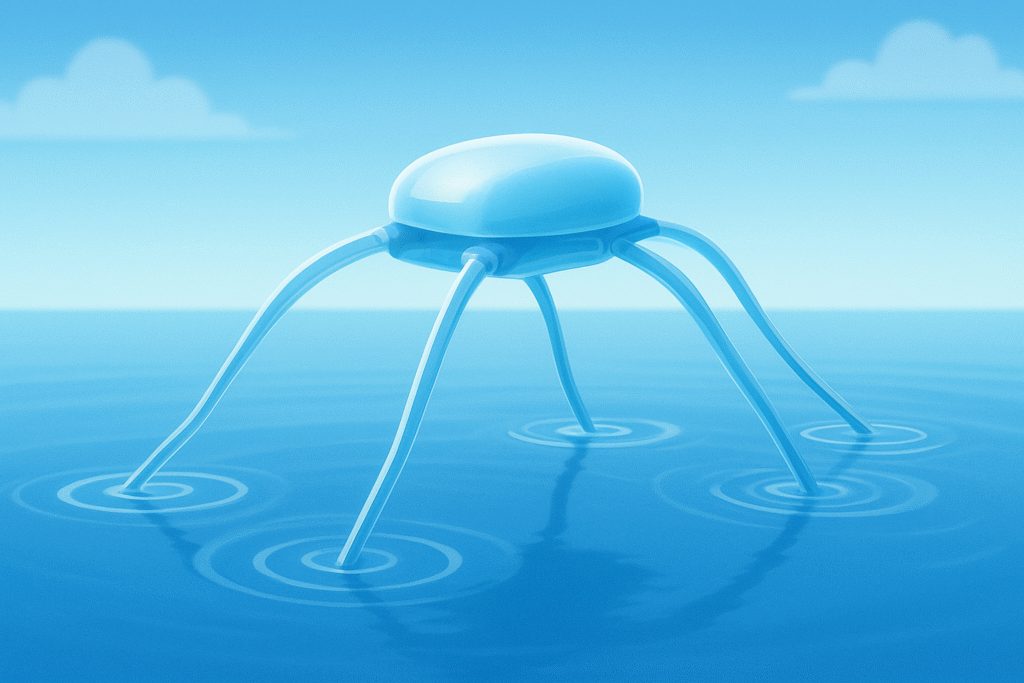

Imagine a world where tiny, leaf-sized machines glide effortlessly across ponds, rivers, or even floodwaters, mimicking the grace of water striders while performing tasks too dangerous or tedious for humans. Thanks to groundbreaking research from the University of Virginia’s School of Engineering and Applied Science, that vision is now closer to reality.

In a study published on September 24, 2025, in Science Advances, a research team led by Professor Baoxing Xu unveiled HydroSpread, a revolutionary fabrication method for creating ultrathin, flexible films directly on liquid surfaces. This innovation has already led to the development of HydroFlexor and HydroBuckler, two insect-inspired robots that can paddle or walk across water.

The discovery is more than just a clever engineering trick — it could transform industries ranging from environmental monitoring and robotics to healthcare and consumer electronics.

What Is HydroSpread and Why It Matters

HydroSpread is a liquid-based fabrication process that allows scientists to build delicate films directly on the surface of water. Unlike traditional methods that required producing films on solid surfaces such as glass and then transferring them — a step that often caused tearing, wrinkling, or material loss — HydroSpread lets water act as the workbench itself.

Here’s how it works:

- Droplets of liquid polymer are released onto water.

- The polymer naturally spreads into ultrathin, uniform sheets.

- A finely tuned laser system is used to cut patterns with extreme precision.

These patterns can be as simple as circles or strips, or as complex as logos and advanced geometric structures. By skipping the risky transfer step, HydroSpread improves efficiency, scalability, and accuracy, making it ideal for applications where softness, flexibility, and durability are essential.

From Films to Functional Robots

HydroSpread is not just about making films — it’s about creating machines that move, adapt, and function in real environments. To demonstrate its potential, Xu’s team built two bio-inspired prototypes:

HydroFlexor

- Moves using fin-like paddling motions.

- Designed for gliding smoothly across water.

- Demonstrates soft robotics principles of gentle, adaptive locomotion.

HydroBuckler

- Walks across water using buckling legs, inspired by the mechanics of water striders.

- Utilizes bending and snapping movements in response to heat, allowing forward motion.

- Offers proof that robots can mimic the agility of insects in aquatic environments.

Both prototypes were powered using infrared heaters. When the layered films absorbed heat, they bent or buckled, generating locomotion. By cycling the heating on and off, researchers controlled speed, direction, and turning radius, proving that repeatable and programmable motion is achievable.

Potential Applications: Where Water-Walking Robots Can Make an Impact

1. Environmental Monitoring

- Detecting water pollution and collecting samples in lakes, rivers, or wetlands.

- Conducting ecological surveys without disturbing natural habitats.

- Patrolling aquatic environments to measure temperature, pH, and toxins.

2. Disaster Response

- Exploring flooded regions after hurricanes or storms.

- Reaching hazardous areas unsafe for human rescuers.

- Assisting in oil spill detection or contamination cleanup.

3. Medical and Healthcare Devices

- Creating wearable biosensors that conform to the skin.

- Building soft medical implants for drug delivery or tissue monitoring.

- Designing flexible surgical tools that adapt to the human body.

4. Consumer Electronics

- Enabling foldable, lightweight displays and smart devices.

- Developing soft, flexible batteries and circuits.

- Opening possibilities for electronics that merge seamlessly with clothing or accessories.

The Science Behind HydroSpread’s Success

HydroSpread works because of fluid dynamics and material science synergy. Water provides a smooth, defect-free platform for polymers to spread evenly. Unlike rigid glass, which introduces stress points, liquid water accommodates the film naturally.

Key advantages include:

- High Precision – Lasers cut clean shapes without cracks.

- Material Efficiency – Less polymer is wasted.

- Scalability – Multiple sheets can be fabricated simultaneously.

- Reduced Failure Rates – Eliminates tears caused during film transfer.

Xu emphasizes: “By letting liquid act as the platform, we reduce complexity and failure at every stage. This opens a new door for manufacturing delicate, soft materials at scale.”

Challenges Facing Water-Walking Robots

Although promising, the research faces hurdles before real-world deployment:

- Energy Sources: Current prototypes require external infrared heaters. Future designs need autonomous power options such as solar cells, magnetic actuation, or embedded micro-heaters.

- Durability: Films must withstand real aquatic conditions, including waves, temperature changes, and contaminants.

- Scaling Up: Moving from lab prototypes to mass-produced, commercial robots will require industrial adoption of HydroSpread.

- Navigation and Intelligence: Current designs move reactively. Future models will need onboard AI for autonomous decision-making.

Why HydroSpread Matters Beyond Robotics

HydroSpread’s potential goes far beyond walking robots. Its ability to create thin, soft, yet durable films directly on liquid surfaces opens opportunities in multiple industries:

- Wearable Technology: Flexible sensors for tracking health metrics.

- Biotechnology: Devices that interact safely with biological tissues.

- Flexible Electronics: Ultra-thin circuits for smart clothing and consumer gadgets.

- Renewable Energy: Thin, flexible solar panels integrated into everyday materials.

This makes HydroSpread not just a robotics innovation but a new manufacturing paradigm.

Competitive Advantage in Robotics Research

HydroSpread places UVA at the forefront of global robotics research. While MIT, Harvard, and Stanford have explored soft robotics for land and air, few have demonstrated water-based robots at this level of sophistication.

By focusing on on-liquid fabrication, UVA researchers have carved out a unique niche. Their approach avoids many pitfalls of conventional robotics, such as rigidity, fragility, and energy inefficiency.

Looking Ahead: The Future of HydroSpread Robots

The team envisions robots that:

- Respond autonomously to natural stimuli such as sunlight, heat, or magnetic fields.

- Operate in swarms, collaborating like schools of fish or colonies of insects.

- Provide low-cost, scalable solutions for governments, healthcare providers, and industries.

Within the next decade, solar-powered HydroSpread robots could patrol oceans, monitor climate change effects, and assist in ecological conservation — all while being safe, lightweight, and environmentally friendly.

Conclusion: A New Era for Soft Robotics

The invention of HydroSpread represents a milestone in materials science and robotics engineering. By fabricating soft robots directly on liquid surfaces, researchers have overcome longstanding barriers to thin-film production and demonstrated lifelike aquatic locomotion.

With potential applications spanning environmental monitoring, disaster response, medical devices, and consumer electronics, this technology could transform how we build and deploy machines in sensitive or dangerous environments.

As Professor Xu and his team continue refining HydroSpread, the future may see water-walking robots becoming as common as drones — quietly gliding across ponds, rivers, and oceans, protecting ecosystems and improving human life.

Reference

Chen, Z., Yin, M., & Xu, B. (2025). Processing soft thin films on liquid surface for seamless creation of on-liquid walkable devices. Science Advances. DOI: 10.1126/sciadv.ady9840